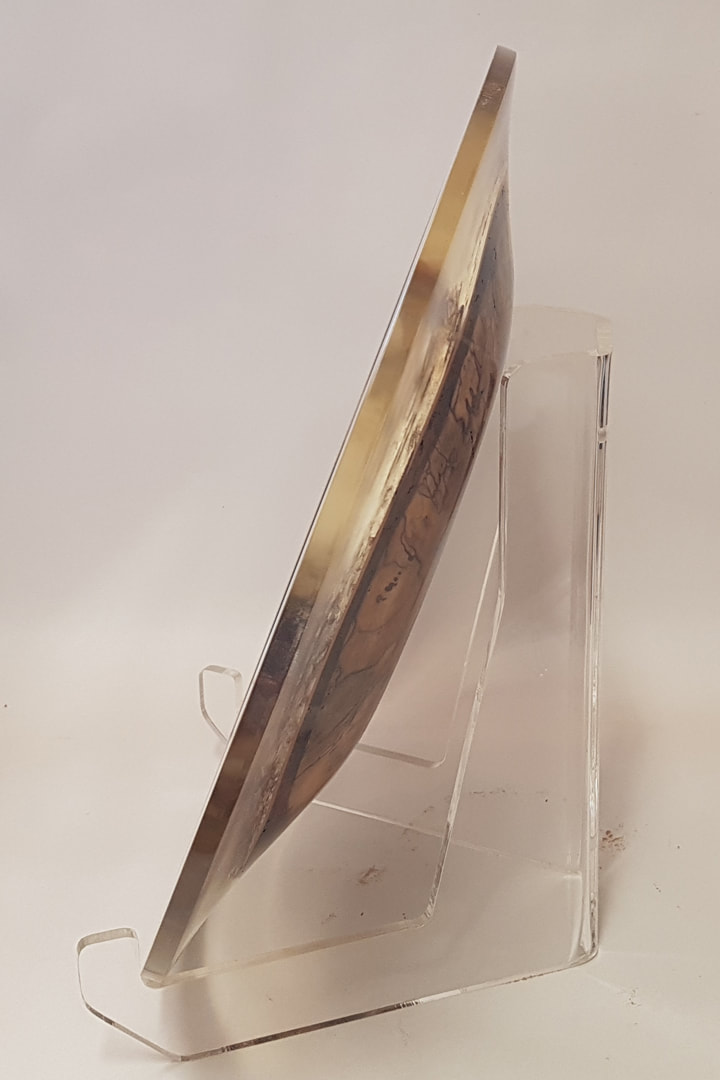

| With the problems in the bottom of the piece cleared up, the piece was reversed on the chuck and the top was turned. In much the same way as the bottom, the top was turned. It took two sessions with a wash coat of epoxy between the them. After the second coat of epoxy the piece was returned to the lathe for sanding. Starting at grit 60 and proceeding through ten grits ending with 1000 the piece was carefully sanded. Three coats of finish were applied. Normally, I put on 5 coats of finish but when I am working with epoxy and wood I try to keep the finishing to a minimum. The wash coat of epoxy makes the wood surface almost as hard as the epoxy so the wood does not absorb the finish. With more than 3 coats on the epoxy you start to be able to see the finish on the surface and it is distracting. I apply salad bowl finish and this makes the piece usable for serving food. This is the finished platter. The piece was entitled "Caught in Time". It had a diameter of 16" and a depth of 2 1/2". There was another piece made from this birch but that is for the next post. Until then... | On the left is one of the details the piece was designed to retain. White birch is known for its curly bark and this iconic curl has been preserved. By the way, clicking on most images in my recent posts will give a larger picture with more detail. |

|

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Categories

All

Archives

February 2019

|

RSS Feed

RSS Feed