You have the Wood...

Jim takes commissions for custom made pieces either from his stock or from wood supplied by his customers. The following sections take you through the things to be considered if you want a piece made from your own material. Read what applies to you and then give Jim a call or contact him here to go over the possibilities.

WoodLess than 1 1/2" thick and dry.

|

PossibilitiesThese pieces were made from the wood on the left.

|

NotesJim can work with paneling, stairs, window frames, decking, flooring or any other wood from a home, farm, cottage or other building.

He avoids pressure treated wood. Chemicals used in this process are released during the turning and sanding stages. These can sometimes be toxic. Wood that is less than 1 1/2" thick, like this barn sheathing and fir paneling are ripped into strips that are 1 3/8" to 1 1/2" wide. These strips are then glued face-to-face to produce a thicker piece of wood. This technique allows Jim to make a memorable piece from very thin wood. Note that the small bowl below is made from sheathing that is not only thin but tapered. |

WoodWood 1 3/8" to 2 1/2" thick and dry.

Rough sawn lumber. |

PossibilitiesThese pieces were made from wood similar to that on the left.

|

NotesCedar dock and deck wood is usually about 1 3/8" thick and can be used as is. As such, it is relatively easy to determine how much wood is required to make a piece. Basically, Jim needs the the diameter plus about 4" in each direction.

For example, the boards on the far left are for a 15" bowl, similar to the bowl on the immediate left. The minimum material required is 19" x 19" - the wood needs to be 19" long and the aggregate width needs to be 19". The same criteria is used for the charger to the left. The minimum for chargers is 15" long and an aggregate width of 15". Cedar is used for docks and deck as it tends to stay straight and warp free. It also weathers well. Rough sawn lumber can be used effectively at 1 1/4" thick if it is straight and flat. This can be achieved to a larger degree by proper drying. More about drying later. Hardwoods such as cherry, maple, walnut and butternut make great salad bowls. Jim prefers thicknesses of 1 3/8" to 1 1/2" as this allows for some of the variances in the wood. |

Various Other Woods |

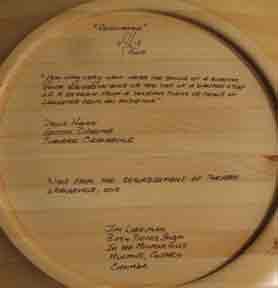

NotesThese are just a few of the many different things that Jim has recycled from the waste pile to functional and decorative pieces.

The recovery and recirculation of any wood is an admirable goal. But for Jim it is the story that the wood has to tell. This is what makes your wood so important. It has meaning to you or the person to whom you wish to give it. Jim puts a synopsis of the story on the bottom. You can also add a short message. This is what changes something ordinary into an heirloom. |

WoodSticks.

|

PossibilitiesThese vases are made from wood similar to that on the left.

|

NotesJim has been making stick bowls and, more recently, vases for many years. He has used various woods including, spalted maple, apple, cherry, walnut, dogwood, staghorn sumac, ash, butternut, wild grapevine and lilac.

He prefers to use sticks that are about 2 1/2" to 3" in diameter. Sometimes sticks of this size are not available especially when working with wild juniper and the like. The sticks can be a single branch of 4 to 6 feet in length or they can be a bunch of shorter ones of 8 to 10" in length each. The aggregate length should be 4 to 6 feet. Jim is allergic to most tropical woods so prefers to work with North American woods. Most of the sticks he works with are from Canada as it is quite difficult to bring raw wood across the border. If something like this is what you want, give Jim a call or contact him and he can go through the options with you. |

Most Everything ElseFresh cut wood.

|

NotesJim takes the larger diameter fresh cut wood to the sawmill to have it cut to boards that are 1 1/2" thick. He then takes the boards and "stickers" them in his garage so that air can circulate on all sides. He leaves them to dry for about 18 months. Some woods such as sumac dry very quickly, others such as lilac take several years.

Sticks are left in the garage for up to a year before being brought into the shop. They are rough cut to length and left to dry thoroughly in the studio. |