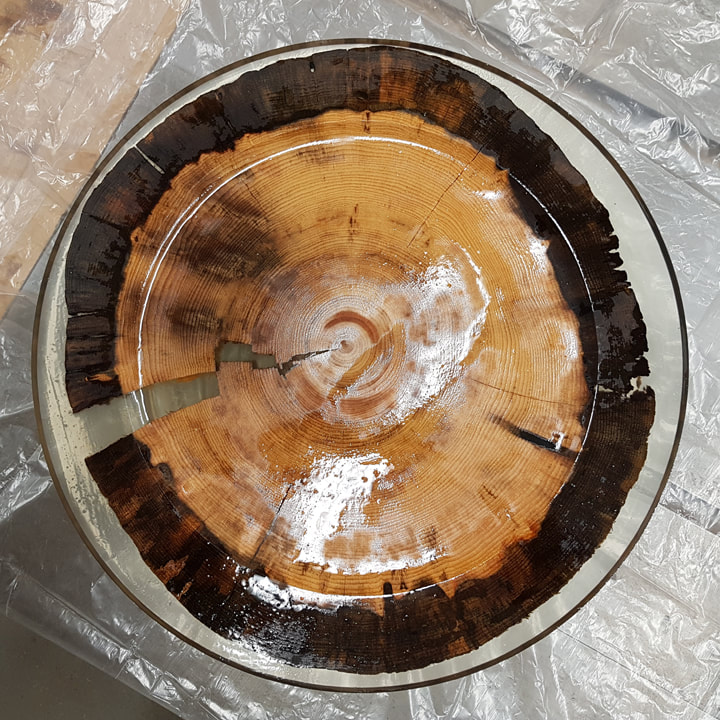

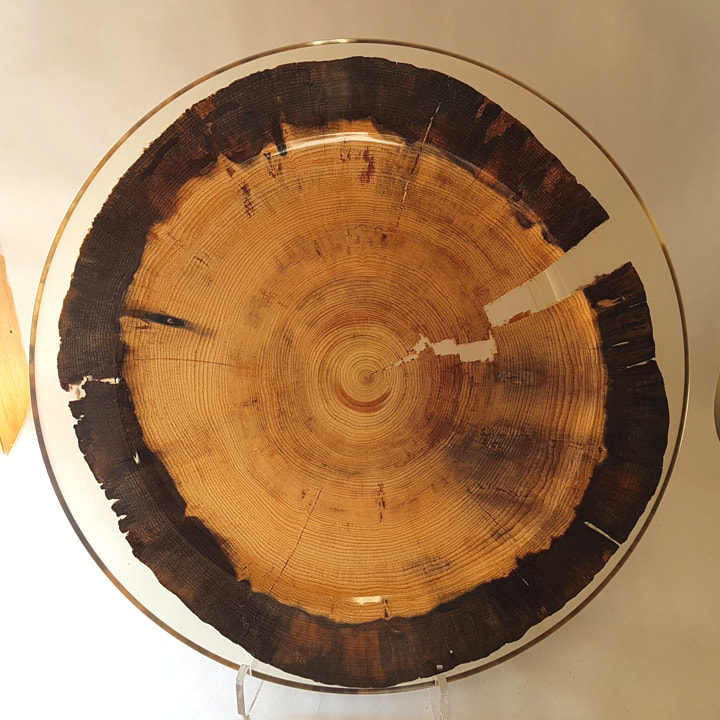

| This piece was similar to the birch in that to cut it lengthwise would have produced too much waste and possibly not enough to make a decent turning. This wood was also taken to the sawmill and cut cross grain. Like the first piece of birch the first slab of pine was put in a mold and both filled and surrounded with epoxy. It was then put on the lathe and turned. In the image on the right you can see the tear out that occurred. To make the wood harder for final turning and sanding, a wash coat of epoxy was applied. The finished platter was called "Gatineau Sentinel". It was 17 5/8" in diameter and 1 1/4" tall. Another piece was made from this pine but that is for the next post. Until then... As in all my recent posts, you can click on any picture to see an enlargement. | The image on the left shows the turning just after the wash coat had been put on. The piece was allowed to sit for several days to allow the epoxy to properly harden. Touch up turning was done then the piece was sanded to grit 1000. |

|

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Categories

All

Archives

February 2019

|

RSS Feed

RSS Feed