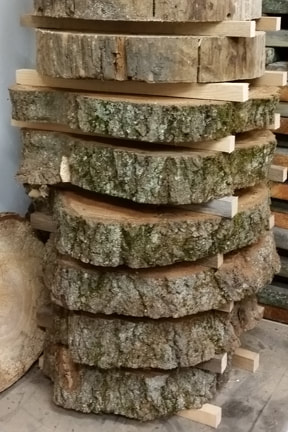

| 'The Watcher' was an exploration in the world of old and rotting wood stabilized with clear epoxy. Since making this piece, I have made a second one and have a third ready to go on the lathe. Each time I tackle one of these I learn something more. This piece started as a very old oak tree from an island in the Pointe au Baril area of Georgian Bay in Ontario. I was able to get a piece from one of the main stems of this tree. The tree was dying and threatening a cottage which necessitated its removal. These trees grow under duress in a challenging climate. Thus they grow slowly and are quite dense. The year rings for this tree averaged about 20 to the inch. This stem which was part of the main trunk was about 19" in diameter, making it close to 400 years old. I was able to get 5 slices from this piece of oak. I also had another piece from the same tree although it was not as dramatic. The slices from the saw milling are stacked to dry in the studio. They sat there for the better part of 6 months. (See image on the right.) Below are the 5 slabs I started to work on. The piece in the foreground was to become 'The Watcher'. On the first one I poured the outside and the inside at the same time. I was pouring at about 1/4" at a time. This way I was able to eliminate almost all the bubbles and keep the epoxy from cracking. I also worked the epoxy into the wood to give it a uniform hardness. The cans around the sides of the mold were for holding the cover I put over the piece while the epoxy hardened. To keep the dust out I would then put a clean, clear garbage bag over the whole works. Notice that the mold is also lined with a clear garbage bag. The epoxy doesn't stick to polyethylene. I no longer use garbage bags to line my molds. I have made a number of molds that are more accurate than the ones I used here and therefore cut down on the amount of work required to clean up the blank down the road. The new molds are designed for quick release and are buffed a number of times using mold release wax. | The first order of business was to clean up the wood and get all the dead bugs, cobwebs and other stuff loosened and away. This was accomplished using compressed air. I was going to , literally, encase the wood in epoxy. This required putting it in a mold and carefully pouring epoxy in the middle and around the edges. I wanted to make a very shallow bowl. On the first piece I did encase it in epoxy but in the making of the bowl I turned about 80% of the epoxy away. On the second piece, I constructed a mold that allowed me to pour the inside up to just beyond the half way point on the thickness of the wood and then pop it out of the mold, turn it over, set it back in the mold and pour the outside up to just over half way again. This gave me about a 30% savings on the cost of the epoxy. The second piece I made from this wood was called 'Witness'. 'The Watcher' and 'Witness' are so similar that I have used images from both pieces for this blog. These two images are of 'Witness'. The epoxy savings are apparent in the image on the left. However, I will show in the next part how using the plastic garbage bag cost me some considerable extra time in finishing the turning of the bowl. Part 2 will be coming soon. Until then... P.S. Remember that you can click on any image to see an enlargement. |

|

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Categories

All

Archives

February 2019

|

RSS Feed

RSS Feed